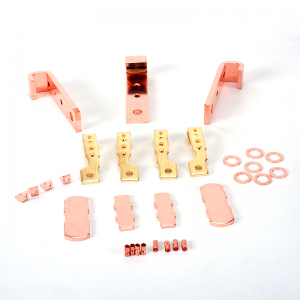

Non-Standard Stamping Parts From Chinese Manufacturers

Electrical stamping parts refer to the hardware used for electrical appliances. There are a lot of hardware used for electrical appliances. Most electrical appliance manufacturers find professional stamping parts manufacturers outside to produce the hardware used for electrical appliances.

Advantages of electrical stamping parts

(1) The production efficiency of electrical stamping is high, and the operation is convenient, and it is easy to realize mechanization and automation. This is because stamping depends on dies and stamping equipment to complete the processing. The number of strokes of ordinary press can reach dozens per minute, and the high-speed pressure can reach hundreds or even thousands per minute, and each stamping stroke may get a punch.

(2) When stamping electrical appliances, because the die ensures the size and shape accuracy of the stamping parts, and generally does not damage the surface quality of the stamping parts, and the life of the die is generally long, the stamping quality is stable, the interchangeability is good, and it has the characteristics of “identical”.

(3) Electrical stamping can process parts with large size range and complex shape, such as small stopwatches of clocks and watches, large car stringers and covers, etc. In addition to the cold deformation hardening effect of materials during stamping, the strength and rigidity of stamping are high.

(4) Electrical stamping generally does not generate chips and chips, and consumes less materials, and does not need other heating equipment. Therefore, it is a material saving and energy-saving processing method, and the cost of stamping parts is low.

Raw material

We support all kinds of metal raw materials. Red copper, brass, copper powder, copper clad steel, 45 # steel plate, 304, new white copper, aluminum, castings, etc.

Product features:

High dimensional accuracy, close blanking

Low comprehensive clearance, low cost and high efficiency;

Process treatment:

Cutting, punching, fine cutting, grinding, polishing, grinding, forming, printing, drilling, chamfering, reaming, cleaning, shaping, oil immersion, degreasing, etc

Processing quantity: there is no limit to the quantity, and the larger the quantity, the better.

Quotation method: electronic negotiation, email, quotation.

1. According to the processing difficulty of hardware stamping sample or drawing;?

2. Processing hours of parts, required equipment and molds;

3. Accuracy tolerance requirements of parts;

4. Other surface treatment and special requirements.